Ever come across challenges managing Preventive Maintenance plans?

EAM/CMMS systems of asset intensive companies can contain large numbers of PMs making them extremely difficult to manage. Updating PMs to improve maintenance creates uncertainty of how to handle potentially obsolete PMs; whether they can be deleted without causing issue. Some PMs are set up to schedule maintenance too frequently, which is time consuming for skilled workers and lowers uptime. Time-based PMs are often not properly superseded by condition-based plans causing unnecessary work orders. Within an asset hierarchy, PMs can be located at inconsistent hierarchy levels or at the wrong level all together.

With this much PM disorganization it becomes difficult to accurately measure resources such as manpower needed for work required. Work prioritization is inefficient, and managers struggle to measure and report on the work backlog or whether work is completed efficiently. Regulations add another layer to these issues, and disorganization makes it difficult to comply with mandatory work.

Knowing the potential challenges asset-intensive organizations may face, let’s look at a specific scenario of one of our clients and the challenges NRX AssetHub helped solve.

The organization is an oil and gas company who use SAP as their EAM/CMMS solution.

Their data challenges included the following:

- ALL maintenance plans and task lists needed to be changed according to a new PM optimization program that was being implemented

- Many maintenance strategies were created based on one strategy not having the correct time package or time units available

- The company decided to incorporate all strategies into one to have all possible packages available

So why can’t these issues be solved in spreadsheet or directly in SAP?

- The data for plant maintenance objects in SAP is very complex. It is time consuming and error prone to fix.

- Changing a strategy on a maintenance plan and task list is very labor intensive

- To ensure all the steps were performed correctly in excel or SAP it would have taken over 12 months of effort

Using AssetHub the task was completed in around 2 months with 90% of the work being automated.

How can NRX AssetHub help optimize PMs and load the data successfully into the target EAM/CMMS?

- Automation programs are used to make all the required changes in the correct order

- Data can be visually inspected and validated in NRX AssetHub prior to being uploaded into the Quality SAP environment for testing and approval

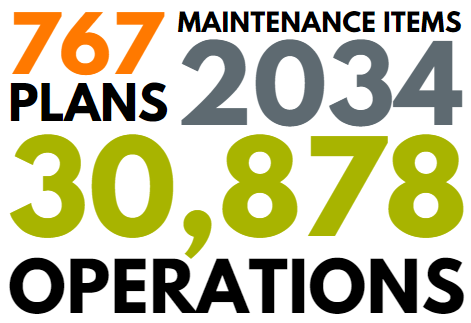

For this specific project, HubHead and the client were able to successfully change 767 plans, 2034 maintenance items and 2034 task lists with 30,878 operations. Furthermore, 767 new maintenance plans and 2034 new maintenance items were created!

NRX AssetHub can help your company deal with planning and maintenance challenges too! Book a demo today or check the solutions we offer on our website!

Share this article