NRX Digital Twin for Maintenance

Find and visualize assets, equipment, and parts faster. NRX Digital Twin is a visual asset, illustrated parts catalogue, and parts management solution that helps Maintenance, Reliability, and Supply Chain professionals visually identify and select the spare parts and vendor documentation they need to efficiently plan and execute maintenance work.

How Our Customers Use Our Digital Twin

- As an electronic Digital Twin directly attached to equipment

- For Visual Parts Selection when choosing parts for CMMS work orders and requisitions

- For building BOMs from vendor-recommended spare parts lists and other information sources

- As a Virtual Plant Navigator to navigate online maps and P&ID drawings of a physical plant to find assets and equipment quickly and accurately

- To digitalize and provide a 360 degree view of all their engineering asset and maintenance information in one easily navigated solution integrated with EAM/CMMS

More wrench time

NRX Digital Twin helps our customers increase wrench time by at least 25% by making it easier and faster for maintenance workers to find information.

%

Better maintenance

NRX Digital Twin helps our customers achieve a savings of at least 10% in ongoing maintenance and operations.

%

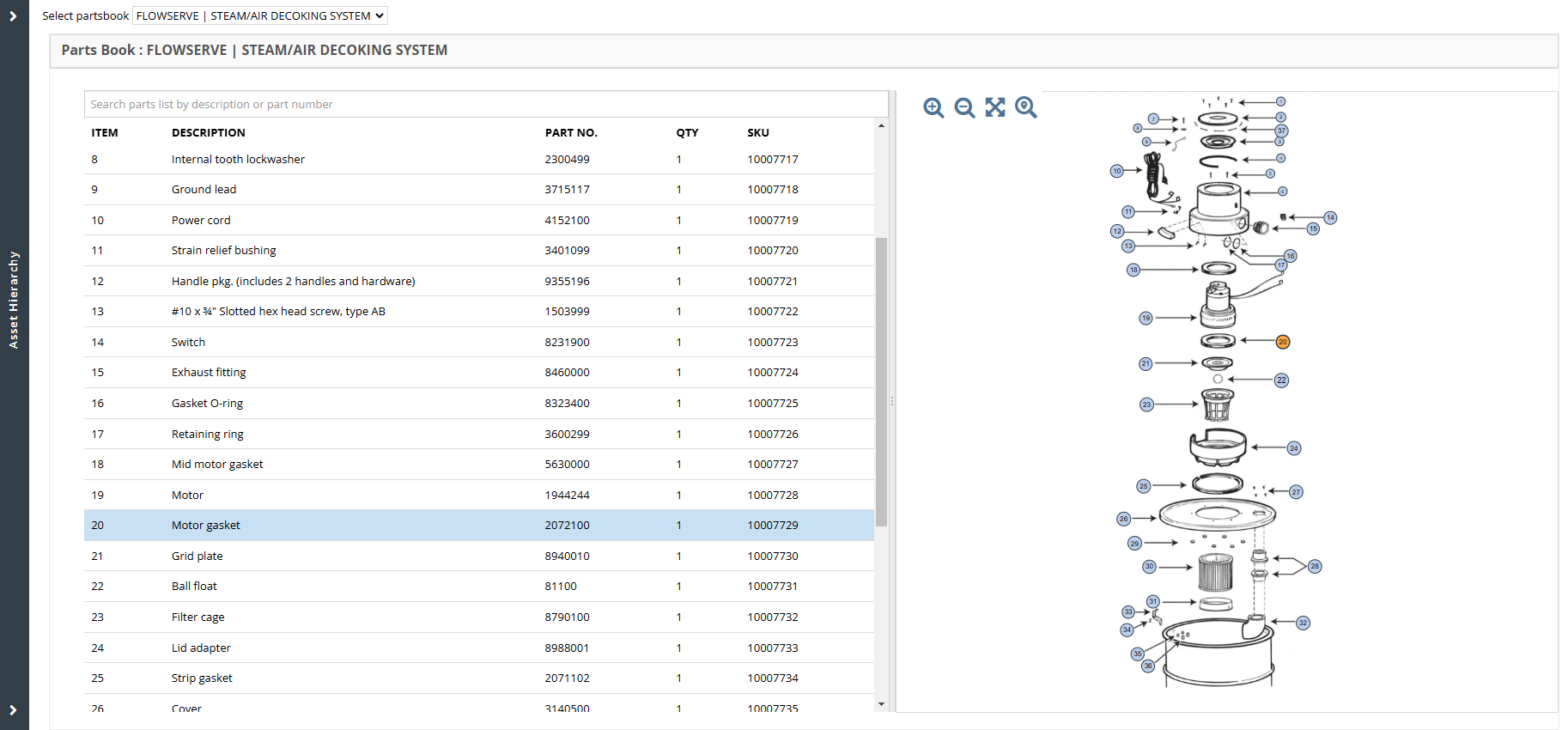

Illustrated Parts Catalog

Maintenance personnel often require spare part information from a maintenance parts catalog when creating maintenance plans, maintenance task lists, or bills of materials. If the parts catalogue is missing or misplaced, or stored at a different location, obtaining the correct information can be very time consuming. This results in wasted time, and can result in errors. In addition, it may lead to ordering or stocking the wrong inventory.

What NRX Digital Twin does

NRX Digital Twin allows our customers to digitalize and consolidate all asset-related documentation, including illustrated parts catalogs, photos, graphical maintenance manuals, P&IDs, and engineering drawings into a single, reliable source, and attach these documents directly to the applicable assets. Our customers load electronic parts catalogs and create hotpoints from drawings and diagrams to parts in a parts list, making it almost instantaneous to locate part numbers. NRX Digital Twin converts parts catalogs from LinkOne, Asset Navigator, and S1000D format automatically.

Benefits

Access illustrated parts catalogues and maintenance manuals for assets quickly. Maintenance personnel no longer waste time looking for parts catalogs. By having the correct information at their fingertips, maintenance staff save time locating part numbers, and reduce errors identifying the correct parts. When maintenance plans and task lists refer to the correct parts, maintenance staff can more easily eliminate duplicate and obsolete inventory, and lessen their reliance on manual processes for material requisitions. Maintenance personnel spend less time looking for parts and information, and more time performing maintenance.

Visual Parts Selection for Work Orders

When creating a work order in an EAM or CMMS system, maintenance staff are often required to include replacement part information for the work to be performed. Without easy access to an electronic parts catalogue, locating the part information can be very time consuming and error prone.

What NRX Digital Twin does

NRX Digital Twin integrates with all major EAM and CMMS systems to link directly from a work order to the Digital Twin for a piece of equipment. Users can visually select a part in an exploded parts diagram, follow a hotpoint link to the part in a parts list, and quickly select the part or parts to be added to the work order or requisition. They specify quantities, and update the work order automatically, reducing errors when ordering parts.

Benefits

Execute work orders faster. Maintenance personnel spend less time looking for parts and information, and execute work orders faster.

Reduce errors in work orders. Maintenance personnel more easily select the correct parts for work orders. Work orders contain more detailed, accurate information, resulting in better maintenance reporting and accounting.

Reduce Supply Chain Expense. Reduce costs associated with misordered and special order parts including rush orders, return shipping, and inefficient procurement.

Build BOMs from Vendor-Recommended Spare Parts Lists

Maintenance staff in asset-intensive companies are challenged to build comprehensive maintenance data for assets, including complete and accurate bills of materials. When access to vendor documentation is limited or the documentation is missing, building a BOM is time consuming, and requires a significant amount of subject matter knowledge.

Often, a vendor uses the same part in multiple assets, or multiple vendors use interchangeable parts. These parts often become duplicated in EAM or CMMS systems, causing companies to unnecessarily stock duplicate parts. Asset-intensive companies frequently find themselves stocking parts for assets that have been decommissioned or removed.

What NRX Digital Twin does

NRX Digital Twin makes it easy to view the list of vendor-recommended spare parts for an asset in the visual parts catalog. AI is leveraged to recommend parts for BOMs based on multiple information sources. Maintenance staff can use the vendor parts list to quickly create a bill of materials. They can use intelligent SKU matching to match the recommended parts to parts in inventory, and add the SKUs to a BOM. They can also see lists of suggested BOMs based on similarities in assets, and quickly associate one or more with an asset.

Benefits

Build BOMs faster. Maintenance personnel can build BOMs quickly from vendor-recommended spare parts lists and other information sources using our AI powered solution.

Eliminate duplicate and obsolete spare parts. Maintenance personnel can visually identify the parts required, creating a more accurate list of required spare parts. Using intelligent SKU matching, they can significantly reduce duplication in inventory and eliminate obsolete inventory.

Virtual Plant Navigation

Maintenance staff in asset-intensive companies often need to locate equipment in enormous facilities, and may waste time physically searching for a piece of equipment in an unfamiliar area, or trying to locate equipment that has moved.

What NRX Digital Twin does

NRX Digital Twin helps users use digital 2D and 3D models for navigating through a large facility to locate a specific piece of equipment. Drill down from the plant or site level in the asset hierarchy to a particular asset, and see exactly where that asset resides on a 2D or 3D site model or on a digitalized P&ID. Conversely, click on a location in the digital twin, and find the location in the asset hierarchy.

Benefits

Find equipment and locations faster in a large facility. Maintenance personnel can quickly locate equipment or locations in a large facility, reducing the time spent looking for equipment. They can spend more time performing maintenance, and less time looking for equipment or locations.

Identify equipment in the asset hierarchy more quickly. Maintenance personnel can use visual equipment location to click on the physical location of a piece of equipment in the digital twin, and quickly and easily find the data for that equipment in the asset hierarchy.

Understand where the equipment fits in the process. Maintenance personnel can quickly understand where the equipment fits in the process from digitalized P&IDs, facilitating shutdowns, planning, scheduling and efficient maintenance.

IBM Maximo Asset Navigator Replacement

As per the software withdrawal notice posted by IBM, the effective withdrawal from market for Asset Navigator was April 29, 2011 with software support ending April 29, 2012. This means that all installations of Asset Navigator are officially out of support and cannot be upgraded beyond Maximo 7.11.

What NRX Digital Twin does

For IBM Maximo customers that require continued Asset Navigator functionality, NRX Digital Twin provides a Maximo-integrated, web-based alternative that has been embraced by the Maximo community.

NRX Digital Twin, just like Asset Navigator, is tightly integrated with Maximo. NRX Digital Twin can be accessed from any of the following screens in Maximo:

- Assets

- Job Plans

- Work Orders

- Purchase Requisitions

- Purchase Orders

- Service Requests

Benefits

Quickly create and publish content. NRX Digital Twin enables users to quickly upload, edit, organize, and merge records to create accurate spares lists for an asset or material.

Visual parts selection. Users can easily create hotpoint links from drawings, illustrated parts catalogues, and exploded parts diagrams to applicable parts lists, allowing maintenance staff to quickly locate the correct parts for their Maximo job plans, work orders, purchase requisitions, and service requests.

Execute work orders faster. NRX Digital Twin helps Maximo users execute work orders faster, and with greater accuracy.

Migrate from Asset Navigator. Customers that migrate to NRX Digital Twin can easily preserve content residing in the Asset Navigator Control Center, seamlessly migrating manuals, hot points, and documents.

What’s Next?

Related Blogs