An Asset Performance Management (APM) solution is important because it allows you to improve the reliability of your asset data and the availability of your physical assets while minimizing risk and operating costs. An APM solution typically includes condition monitoring, predictive maintenance, asset integrity management, and reliability-centered maintenance.

Why is APM Analysis Important?

APM analysis is important because it helps ensure asset reliability. By conducting APM analysis, you can help your assets achieve peak performance while minimizing downtime.

What Asset Data Do You Need for Successful APM Analysis?

Once you have the basic information required in your EAM system, you may want to think about additional useful asset information that can be included in your EAM. Specifically, what asset data can help you support successful APM analysis.

Maintenance Plans and BOMs

Accurate BOMs and maintenance plans are required to ensure that maintenance technicians can identify what and when equipment parts are needed to complete work orders. BOMs should consist of clear and concise information that makes it easy for technicians to order, identify, and select the correct parts quickly.

Equipment Categorization and Key Characteristics Captured

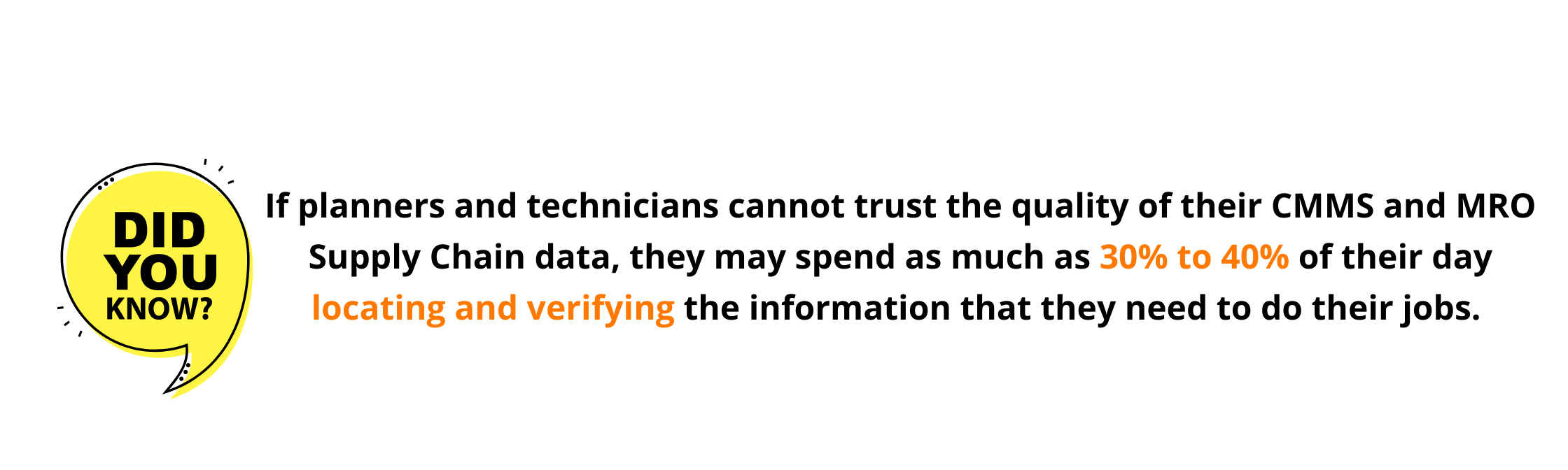

For your EAM system to support successful APM analysis, your equipment should be categorized with key characteristics captured. Without this information, you cannot experience the total value of the investment you have made in your APM software. Ensuring your equipment is correctly categorized in your EAM allows you to analyze and compare failure data consistently across equipment categories. Verifying your EAM includes key characteristics of your equipment improves productivity as it reduces the time that maintenance technicians must spend searching for equipment details manually.

Process-Oriented Asset Hierarchy and International Standards

Even if your EAM system contains all the above-listed asset data, many companies fail to realize the potential value of their APM technology without a strong data foundation. As a result, they may struggle to identify and correct underlying issues. APM software is only as good as the data on which it is based.

Without a process or functionally organized asset hierarchy it is almost impossible to do APM analysis efficiently. Unfortunately, most companies have not set up their assets in a well-organized process-oriented hierarchy. The process-based asset hierarchy helps you understand how assets are used and what process they are part of. The same type of pump could be production and safety critical as part of a critical process but not be important at all used for something else. To determine criticality efficiently and accurately you need a process-based hierarchy.

International standards such as ISO 14224, RDS-PP, or KKs help asset-intensive companies in various industries adopt proper process or functionally oriented standards for asset data across their company’s facilities. Implementing an international standard makes it easier to determine asset criticality and recommended actions, both of which heavily influence the creation of maintenance strategies for your operations. In addition, a well-defined corporate standard provides a system by which to organize assets and their locations in a hierarchy, makes it easier to monitor assets, complete reliability analysis, and improves maintenance efficiency.

Consider Reviewing and Correcting Your Asset Data

An EAM migration is ideal for reviewing and correct your asset data to ensure that it is optimal for successful APM analysis. Migration provides an excellent opportunity to make changes to your data because you already need to bring your data out of your current EAM or CMMS system.

HubHead Corp., powered by NRX AssetHub, provides asset-intensive businesses with world-class software for visualizing, building, editing, organizing, governing, and sustaining high-quality asset and maintenance master data for their EAM and CMMS systems. If you would like to learn more about how we can help you review your asset data to ensure successful APM analysis, feel free to book a demo, and our team would be happy to help!

Your EAM is Only as Good as the Data you Feed it

Common Problems with Asset Data Management

Effective Asset Data Management Is Your Company’s Love Language

Share this article